Building Envelope Materials is on a mission to develop quick inexpensive minimally disruptive technologies for reducing the global warming impact of buildings to zero.

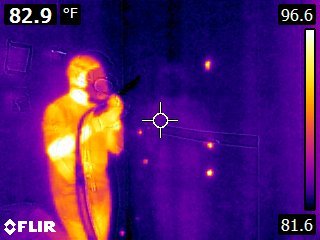

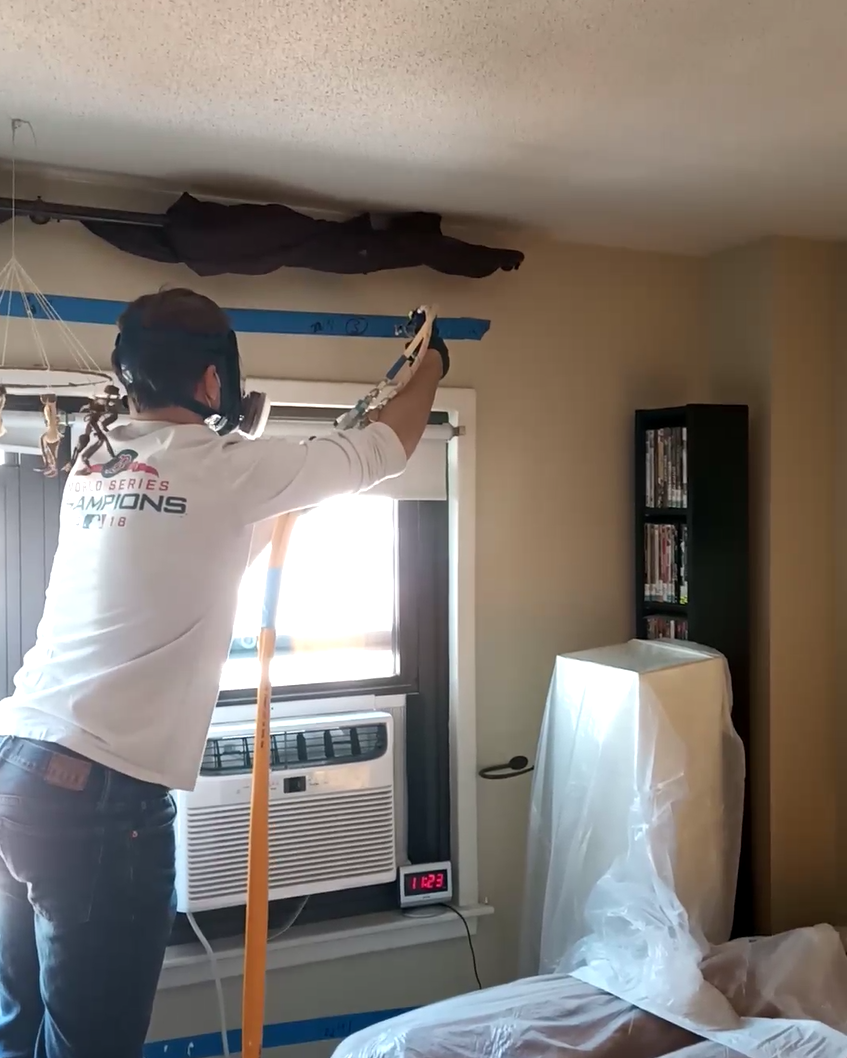

Our mission began in 2014 with a small grant from the Massachusetts Clean Energy Center (MassCEC) to develop a way to inject highly insulating closed cell polyurethane foam into under-insulated fiberglass filled wall cavities. We further developed Pinhole Insulation® through additional major grants from the MassCEC, the US Department of Energy, MassRobotics, CertainTeed/Saint Gobain, Eversource and several other utilities. Over the past 10 years, we have injected well over 40,000 cavities in buildings from Southern Florida to Northern Maine.

The results have been phenomenal. We reduce thermal energy use and associated carbon emissions by 20 to 30%. And the process is quick and cost-effective. We can insulate 6 to 12 occupied apartments in a single day. Simple payback is often one to two years…not including significant additional savings on heat pump conversion costs.

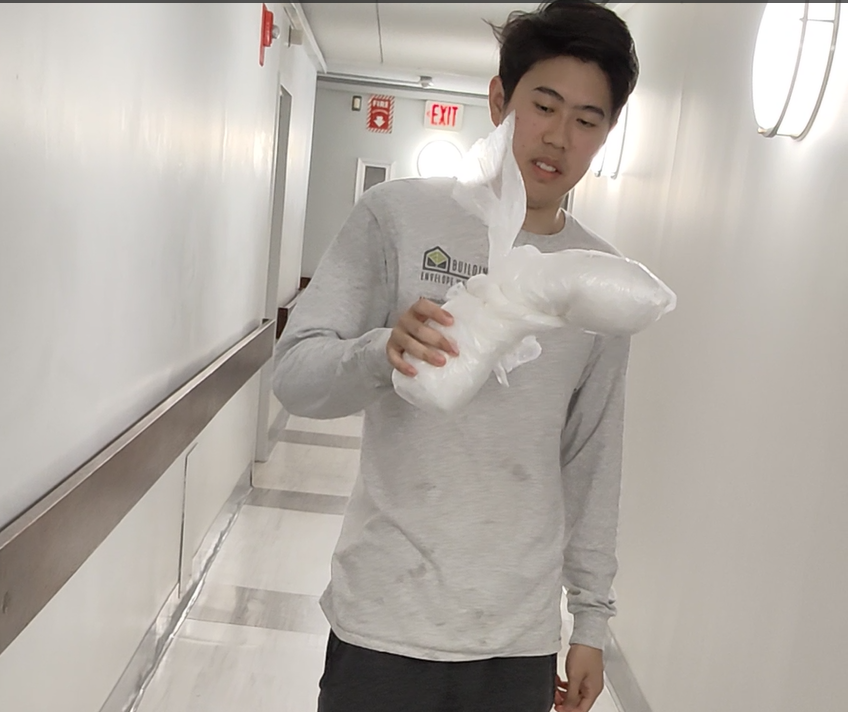

Meet The BEM Team

Doug lamm

CEO

Doug developed the original Pinhole Insulation® process for retrofit insulation of wall cavities. Prior to BEM, Doug worked for 30 years as a management consultant to specialty materials companies.

Email: dlamm@bematerials.com

Alex bell

DIRECTOR, ENGINEERING

Alex designs and develops new devices, software and materials for use in BEM's Pinhole Insulation® process. Alex has also worked for 7 years developing foam-based energy storage systems at SustainX and General Compression.

Email: abell@bematerials.com